◇ Materials not suitable for crushing (take PSX-600 horsepower type as an example)

▷ Dangerous objects: sealed containers, pipes, etc.; objects that may cause explosions, fires, etc.;

▷ Scrap cars, etc.: main bodies other than passenger cars; engines, converters, differential gears, tires; closed high-pressure gas cylinders (hydraulic cylinders, etc.); large materials that need to be cut off or objects with a weight of more than 150kg;

▷ Others: iron block 10kg or more; steel plate 5mm or more or 20kg or more; section steel and rail with thickness of 5mm or more; steel pipe with wall thickness of 5mm or more×φ250×500L; cables, steel wires, steel wires; hardened shafts and sleeve parts; motors , Transformers, compressors; ingots, blanks and similar solid materials; materials with a diagonal size of more than 2000mm.

▷ The scrap metal input must be free of explosive, flammable and toxic liquids, gases and dust.

The following materials cannot be put into the equipment:

• Dangerous and explosive materials

• Natural objects or combustion-supporting objects

• Toxic or corrosive substances

• Refrigerant

• Transformer oil

• Asbestos

• Ammunition

• Airtight cylinders, containers/fuel tanks or other airtight hollow bodies

• Battery

• Pyrotechnic air bag and belt tensioner

• Materials whose size or shape may hinder the rotor (ie, unbreakable materials with a diameter greater than 180 mm).

Magnetic separator

◇ Features

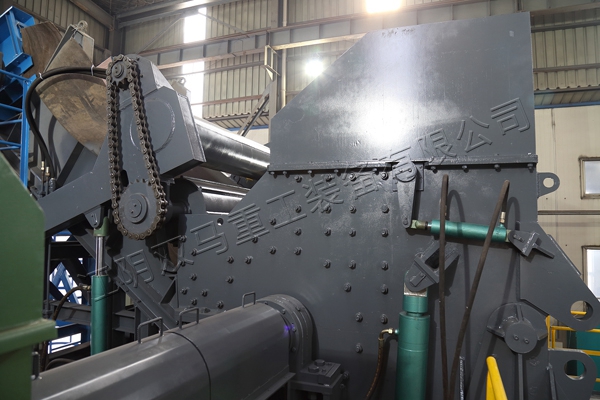

The main structural features of the crusher: the lining board and the hammer head adopt special wear-resistant materials to increase the service life; and the hammer head adopts a movable installation structure. Once an unbreakable object enters the crusher, it can be thrown and avoided. The non-crushable safety door specially designed for the crusher can be opened to remove it from the machine, thereby reducing the damage to the machine.

The core function of the hydraulic roller compactor: it is the feed pre-processing machine of the crusher, which can pre-compress thin shells and light metal components with larger dimensions and smoothly enter the scrap steel material at the feed inlet of the crusher, thereby expanding The scope of processing materials of the crusher. At the same time, it plays a vital role in improving the production efficiency of the crusher.

Discharge belt conveyor

Working principle and process

◇ Working principle

The scrap steel crushing production line uses the principle of hammer hitting. Driven by a high-speed, high-torque and high-voltage motor, the hammer on the rotor of the main machine takes turns to hit the object to be crushed into the cavity, which is formed between the liner and the hammer. Space, tear the material to be crushed into crushed materials that meet the specifications, and then under the action of magnetic equipment, high-purity crushed steel can be obtained.

Dust removal equipment

◇ Work process

The material is loaded on the scale conveyor by the hydraulic grabbing machine (or electromagnetic chuck) (note that the feeding material must be even), the material is lifted to the double-roller feeder through it, and the material is squeezed by the double-roller to enter the crusher in a suitable size . The crusher is equipped with a water spray port, and the sprayed water can avoid dust and reduce the temperature of the hammer. For large, thick and unbreakable scrap steel, it can be ejected through the discharge door of the crusher. The crushable materials fall into the vibrating conveyor from the grid hole after crushing, and then are sent to the discharge belt conveyor, and then to the magnetic separation system. In the magnetic separation system, the broken steel is sucked up and sent to the stacking conveyor, and other materials fall onto the non-magnetic material conveyor through the hopper at the lower part of the magnetic separation system. The stacking conveyor can move around a fixed axis, and the crushing production line can be stacked in a large fan-shaped area. A suspended magnetic separator is installed above the non-magnetic material conveyor for secondary magnetic separation, which can suck out the remaining magnetic ferrous metal on the non-magnetic material conveyor, reduce the amount of scrap steel missed by the electromagnetic drum of the magnetic separation system, and improve the Recovery rate. The material separated by the non-magnetic material conveyor can be transported to the sorting workshop for the sorting personnel to manually select on it, and the non-ferrous metals such as copper and aluminum caught in the non-magnetic material can be selected to improve the recycling efficiency.

Product model table

| Model | Spindle Specification | Coveryor Width | Main Motor Power | Producition Rate |

| PSX-280 | 4050 | 1200 | 200 | 3-5 |

| PSX-600 | 5070 | 1250 | 450 | 8-12 |

| PSX-800 | 6080 | 1800 | 600 | 12-20 |

| PSX-1200 | 6886 | 2000 | 900 | 20-25 |

| PSX-1600 | 68104 | 2000 | 1200 | 25-40 |

| 68104 | 2500 | 30-45 | ||

| PSX-2000 | 68104 | 2500 | 1500 | 40-60 |

| 80104 | 2600 | 40-70 | ||

| PSX-3000 | 80104 | 2600 | 2250 | 50-80 |

| PSX-4000 | 80104 | 2600 | 3000 | 60-100 |

| 98104 | 2600 | 70-100 | ||

| PSX-6000 | 98104 | 2600 | 4500 | 100-120 |

| PSX-10000 | 98114 | 2800 | 7500 | 110-150 |

Tianjin port airlines 1200T wind power installation platform leg project 1

Tianjin port airlines 1200T wind power installation platform leg project 1 Tianjin port airlines 1200T wind power installation platform leg project 2

Tianjin port airlines 1200T wind power installation platform leg project 2 Offshore cranes cylinders

Offshore cranes cylinders Matrix column

Matrix columnCONTACT USNational Hotline:0510-86191088

Jiangyin Shuangma Heavy Industry Equipment Co.,ltd.

Add: No.8, Xiaguang Road, Gaoan Village, Xuxiake Town, Jiangyin City

Contacts: Mr.Shen

Tel: 0510-86191088

Fax: 0510-86191800

Web:www.shuangmacn.com

E-mail: sm@shuangmacn.com

Jiangyin Shuangma heavy industry equipment Co.,ltd. Add: No.8, Xiaguang Road, Gaoan Village, Xuxiake Town, Jiangyin City

Contacts: Mr.Shen Fax: 0510-86191800

Http://www.shuangmacn.com E-mail: sm@shuangmacn.com

All rights reserved © 2015 Jiangyin Shuangma heavy equipment Co.,ltd Support: Jiangyin huaxin